In this week’s edition of the automotive guide, we will be learning about one of the strongest elements in a car. Brakes are a crucial component of any car, playing a vital role in ensuring your safety on the road. They are designed to slow down or stop the vehicle whenever needed, allowing you to maintain control and avoid accidents.

How Car Brakes Work?

When you press the brake pedal inside the car, you activate a hydraulic system that transmits pressure to the brake calipers. The calipers, in turn, squeeze the brake pads against the spinning brake discs. This contact between the brake pads and discs generates a significant amount of friction, which converts the kinetic energy of the moving car into heat energy. This heat energy is dissipated into the air, and the friction causes the car to slow down or stop.

History

Car brakes have a complex history of development, with various inventors and innovations contributing to their evolution. Early automobiles in the late 19th century lacked dedicated brake systems, relying on rudimentary methods like tire pressure or external hand-operated levers for braking. The introduction of drum brakes in the early 20th century marked a significant improvement, featuring expanding brake shoes within a drum attached to the wheel.

However, it was the development of hydraulic brakes, attributed to inventors like Frederick William Lanchester in 1902, that brought more reliable and consistent braking performance to cars. Disc brakes, known for their superior cooling and braking capabilities, gained popularity in the mid-20th century when Jaguar became one of the first manufacturers to adopt them in production vehicles.

Types Of Braking Systems

Drum Brakes:

Drum brakes have brake shoes inside a drum attached to the wheel. When you press the brake pedal, the shoes expand against the inner surface of the drum, creating friction to slow the vehicle. They’re commonly used for rear wheels but are less efficient and can overheat.

Disc Brakes:

Disc brakes use a hydraulic system to apply pressure on brake pads that grip a rotating disc attached to the wheel. Friction between the pads and disc stops the vehicle. They’re known for efficient heat dissipation, making them reliable and less prone to fading. Typically, they’re used on a car’s front wheels.

Both systems can use hydraulic fluid or pneumatic pressure. Some heavy vehicles use an electric-magnetic brake system, but the most common setup in modern cars is hydraulic disc brakes. However, the most common setup now found in most cars is disc brakes using a hydraulic system. Further discussion in the article will revolve around this particular braking system.

What Are The Components Of a Disc Brake System?

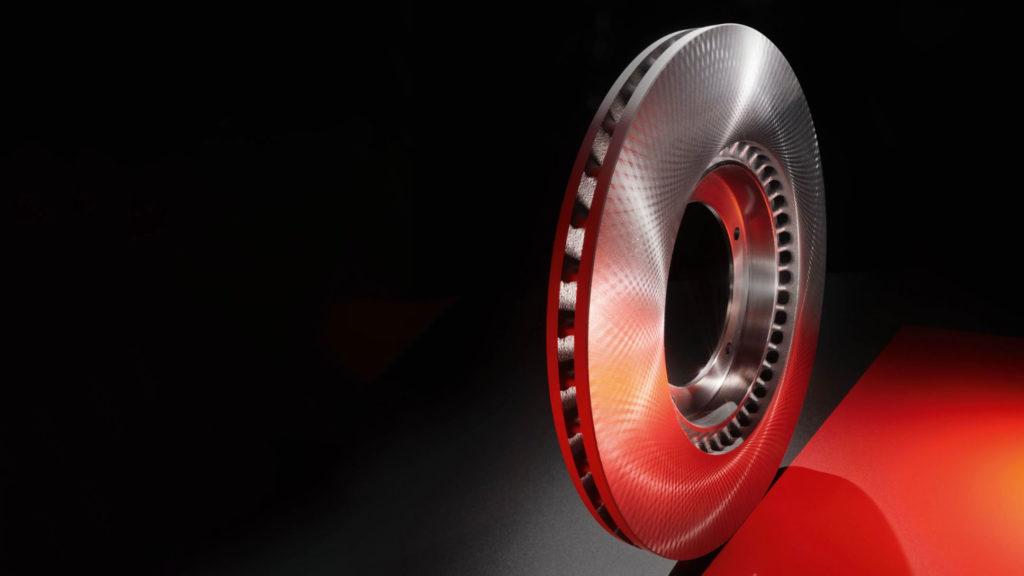

Brake Rotor

The brake disc, also known as the rotor, is a flat, circular metal component attached to the vehicle’s wheel hub. When the brake pedal is pressed, brake pads are pressed against the brake disc’s surface, creating friction and slowing down the rotation of the wheel.

What Materials are used for making a Brake Rotor?

- Cast Iron: Made from gray cast iron, these rotors are durable and cost-effective under normal conditions. They can rust and are heavier.

- Carbon Composite: Composed of carbon fibers and matrix material, these rotors are lightweight, enhance handling, and provide excellent heat dissipation. Common in high-performance vehicles but pricier.

- Reinforced Carbon-Carbon (RCC): Known for extreme heat resistance and performance, these rotors are expensive and rare in everyday vehicles.

- Steel: Steel rotors, made from cast or carbon steel, are durable and cost-effective for standard driving. They may be heavier and less suitable for high-performance use.

Types of Brake Rotors

- Standard (Solid) Rotors: Flat and solid, these rotors are durable and cost-effective for everyday driving and most vehicles.

- Vented Rotors: These have internal vanes or fins for better heat dissipation. They’re commonly used in high-performance and sports cars.

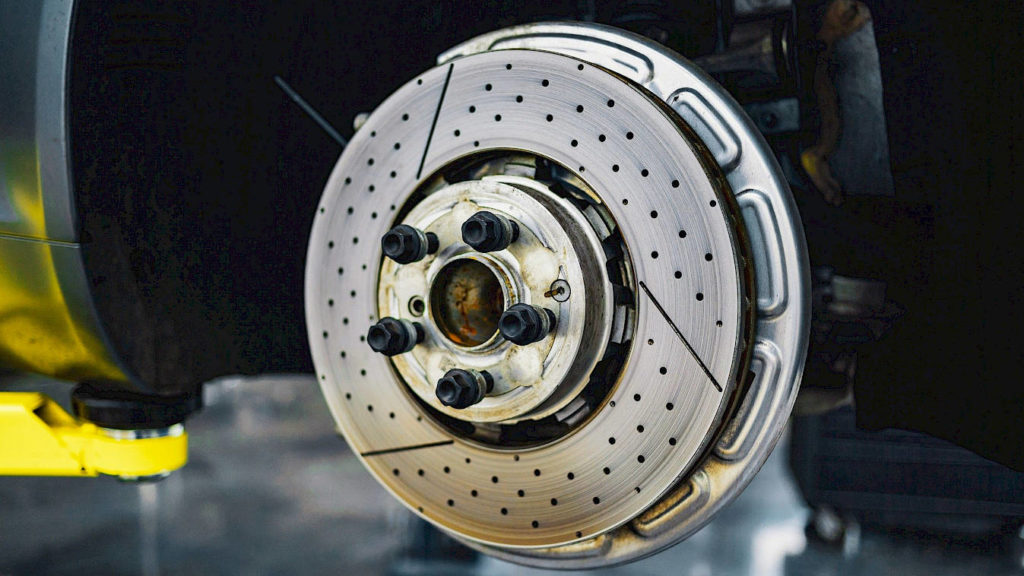

- Slotted Rotors: Featuring slots on the rotor surface, they aid in heat and gas dispersion, reducing brake fade and enhancing wet weather performance.

- Drilled Rotors: These rotors have holes drilled through them, reducing heat buildup and offering a cosmetic enhancement. Effective for preventing brake fade and improving wet weather performance.

- Slotted and Drilled Combination Rotors: Combining both features for improved heat dissipation and braking performance, offering a balance between heat management and enhanced braking. Suitable for various applications.

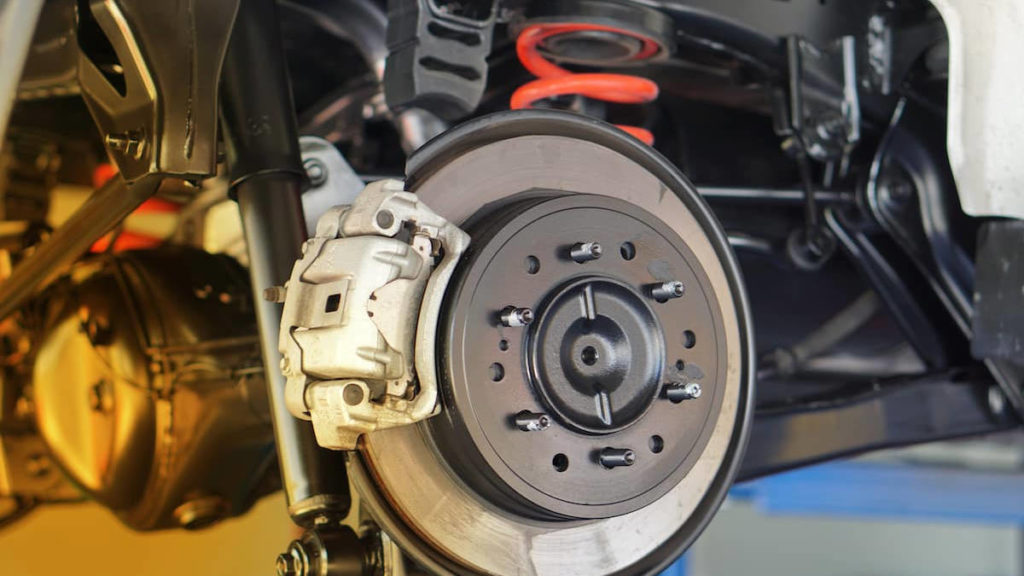

Brake Caliper

The brake caliper is a housing that contains brake pads. It’s positioned on either side of the brake disc and is responsible for applying pressure to the brake pads. When hydraulic pressure is applied, the caliper’s pistons push the brake pads against the disc, creating the necessary friction for braking.

Types of Brake Calipers:

- Floating Calipers: Common, cost-effective design with one or two pistons that slide to apply brake pressure.

- Fixed & Radial Calipers: High-performance calipers with pistons on both sides for even pressure and heat dissipation. Radial calipers offer improved rigidity, heat dissipation, and braking precision, particularly during aggressive riding or driving.

- Opposed Piston Calipers: Combine the benefits of fixed and floating calipers for balanced performance.

- Monobloc Calipers: Rigid, one-piece construction for superior performance and durability, often used in high-performance vehicles.

- Sliding Calipers: Similar to floating calipers but with lateral sliding for even pressure, found in many modern cars.

- Dual Calipers: Used in racing and high-performance cars, featuring two calipers per wheel for enhanced braking control.

- Electric Calipers: Modern innovation using electric actuators for precise control, found in some electric and hybrid vehicles.

Brake Caliper Piston

The brake caliper piston is a key part of a disc brake system. It’s responsible for translating hydraulic pressure, generated when you press the brake pedal, into force that pushes the brake pads against the brake disc. This contact creates friction, slowing down or stopping the vehicle. When you release the brake pedal, the piston retracts, allowing the brakes to disengage. Usually, a traditional brake caliper will have one or two sets of pistons to push the brake pads. Performance vehicles will have around 8 to 10 pistons evenly spreading pressure to the brake pads for superior braking performance.

Brake Pads

Brake pads are rectangular or oval-shaped components that come into direct contact with the brake disc. They are typically made of friction material, such as semi-metallic, ceramic, or organic compounds, designed to withstand heat and provide consistent braking performance.

Types of Brake Pads:

Standard Brake Pads:

- Material: Typically organic or semi-metallic compounds.

- Common in everyday vehicles, it offers balanced braking performance, noise levels, and dust control for regular driving.

Semi-Sintered Brake Pads:

- Material: Blend of metallic particles and organics.

- Combines characteristics of organic and sintered pads for a versatile performance suitable for a wide range of vehicles.

Sintered Brake Pads:

- Material: Compressed metallic particles.

- Known for exceptional heat resistance and durability, ideal for heavy-duty and high-performance applications.

Kevlar Brake Pads:

- Material: Includes Kevlar fibers.

- Offers excellent heat resistance and durability, preferred for racing and high-performance vehicles.

Hybrid Brake Pads:

- Material: Blend of ceramic, organic, and semi-metallic elements.

- Balances braking performance, noise reduction, and dust control, suitable for various driving conditions.

Carbon Kevlar Brake Pads:

- Material: Combines carbon and Kevlar fibres.

- Favoured in racing and high-performance settings, offering consistent, powerful braking in extreme conditions.

Regenerative Brake Pads:

- Specialized pads aid energy conversion during braking, enhancing efficiency in eco-friendly vehicles.

Brake Fluid

Brake fluid serves as the medium for transmitting hydraulic pressure from the brake pedal to the brake calipers or wheel cylinders. When the brake pedal is pressed, it activates the master cylinder, which generates hydraulic pressure. This pressure is then transmitted through brake lines filled with brake fluid to the brake components at each wheel. As a result, the brake caliper pistons in disc brake systems are pushed, causing the brake pads or shoes to make contact with the brake disc or drum, generating the friction needed to slow down or stop the vehicle.

Types Of Brake Fluid:

Brake fluid is available in several types or classes, each designated by a specific DOT (Department of Transportation) rating. These ratings indicate the fluid’s composition and performance characteristics. The two most commonly used types of brake fluid are DOT 3 and DOT 4, with DOT 5 and DOT 5.1 being less common.

- DOT 3 Brake Fluid: Common glycol-based fluid with a boiling point around 401°F (205°C). Suitable for everyday driving.

- DOT 4 Brake Fluid: Enhanced glycol-based fluid with a boiling point of approximately 446°F (230°C). Used in demanding conditions, like high-performance vehicles.

- DOT 5 Brake Fluid: Silicone-based fluid with a high boiling point of around 500°F (260°C). Less common, used in specialized applications, but not compatible with glycol-based fluids.

- DOT 5.1 Brake Fluid: High-performance glycol-based fluid with a boiling point above 500°F (260°C). Used in racing and extreme braking scenarios. Always follow the manufacturer’s recommendations for brake fluid type and maintenance intervals to ensure safe braking performance.

Master Cylinder

A master cylinder is a crucial part of a vehicle’s brake system. It converts the force applied to the brake pedal by the driver into hydraulic pressure, which is used to engage the brakes. This hydraulic pressure is transmitted through the brake lines to the brake calipers or wheel cylinders, enabling the vehicle to slow down or stop. The master cylinder also contains a reservoir for brake fluid, ensuring a constant supply and maintaining proper hydraulic pressure. It plays a pivotal role in the safe and effective operation of a vehicle’s brakes.

Types Of Master Cylinder:

- Single-Circuit Master Cylinder: This type has a single hydraulic circuit for all brakes, which is less common in modern vehicles due to safety concerns.

- Dual-Circuit Master Cylinder: Found in most modern vehicles, it has two separate hydraulic circuits for front and rear brakes, providing safety in case of a circuit failure.

- Tandem Master Cylinder: This design features two pistons for precise front and rear brake control, commonly used in modern vehicles.

- Integrated Master Cylinder/Brake Booster: This combines the master cylinder and brake booster into one unit, saving space and simplifying the brake system, often seen in power brake systems.

- Remote-Mount Master Cylinder: Used in high-performance or custom vehicles, it’s mounted separately from the brake pedal, offering design flexibility and accommodating modifications.

That is everything you need to know about the car’s disc brake system. In this guide, we have only discussed the hardware part of the car’s brake. In recent times due to the rising concern for passenger safety, these hardware are now supported by intelligent and smart electronics to offer the safest possible drive. Stay tuned for next week’s series of Detailed Guide To Automotive Terms featuring Braking Electronics.

Looking to buy a car? Here are used cars for sale in the UAE and new cars for sale in the UAE. Also here is a beginner’s guide that will help you understand the basic car terminologies.

Other Automotive Guides:

The post Get To Know Your Car Better: A Detailed Guide To Automotive Terms — Brakes appeared first on Dubi Cars - New and Used Cars.

from Dubi Cars – New and Used Cars https://ift.tt/ZO3STyr

https://ift.tt/bTd1pX9